-

What work should be done before the rivet nut is assembled? Ⅱ

3. The rivet nut gun can be adjusted according to the needs during the adjustment stroke. It is worth noting that: when the single-sided bolt length adjuster, open the two handles to adjust the front riveting of the sleeve slightly exposed to slightly longer than the rivet nut. length, and finall...Read more -

What work should be done before the rivet nut is assembled? Ⅰ

1. First check the muzzle when the screw is not assembled correctly, choose the nut that is properly riveted according to the size. 2. Pay attention to whether the lower rivet nut will be deformed or displaced, and adjust the angle of the operating rod according to the actual situation.Read more -

How to test the strength of rivet nuts

1. Screw the rivet nut into the thread core, but ensure that the applied load lasts for 15 seconds. At this time, if the strength is good, there will be no fracture. 2. Screw the rivet nut into the threaded mandrel to apply the load until it breaks, and the break should not occur at the intersect...Read more -

Why are aluminum blind rivets magnetic?

Because the fact that the aluminum blind rivet we are referring to now is not all aluminum, it is composed of an aluminum nail shell and a carbon steel tie rod, and carbon steel is magnetic, so the aluminum blind rivet is magnetic. https://www.yukerivet.com/rivets-aluminum-steel-round-head-5-prod...Read more -

Why are stainless steel double-sided countersunk head blind rivets semi-stainless steel?

Because the whole mandrel is pulled out after the double-sided countersunk head blind rivet is riveted, the material of the mandrel will not affect the corrosion resistance of the stainless steel double-sided countersunk head blind rivet. Moreover, stainless steel is much more expensive than iron...Read more -

Which blind rivets are waterproof?

Both closed blind rivets and lantern blind rivets are waterproof.Read more -

What is the difference between countersunk head blind rivets and round head blind rivets?

Round head blind rivets do not need chamfering, they will protrude from the surface after riveting, while countersunk head blind rivets should be chamfered by 120°, and they will be on the same plane as the plate after riveting.Read more -

When riveting products, how to choose round head blind rivets and countersunk head blind rivets?

This mainly depends on the final effect we achieve on the product. After the round head is pulled, there will be a round head on the surface. After the countersunk head pull stud is pulled, the surface can be kept flat, but the premise is that the countersink must be drilled. A little troublesome...Read more -

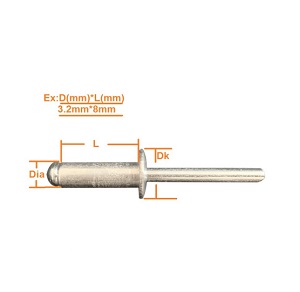

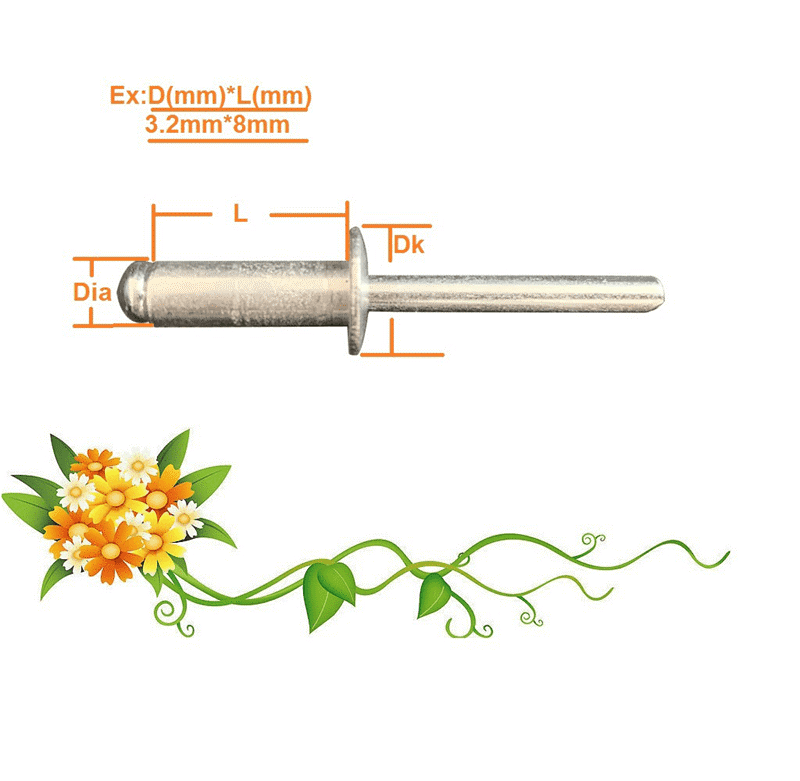

How many times the original outer diameter of aluminum blind rivets?

About 1.5 times, but this is only a reference value, and the riveting changes of different types of aluminum rivets are different.Read more -

What is the difference between stainless steel blind rivets and aluminum blind rivets?

1. The two materials are different and the performance is different. The hardness of stainless steel is much higher than that of aluminum, so the tensile and shear resistance of stainless steel is relatively large, and it is more suitable for workpieces with high fastening strength; the tensile a...Read more -

Why are the structural blind rivets recommended by the masters for decades?

This is because when the structural blind rivet is riveted, the mandrel can be locked into the rivet body, which makes both the rivet body and the mandrel on the same shear plane, providing users with shear resistance. The tensile strength is also improved simultaneously. The high clamping load g...Read more -

Why can structural blind rivets replace solid rivets?

Structural rivets can be used to replace single-layer solid rivets because only one side of the workpiece is used for installation, but single-layer solid rivets can only be installed using both ends of the workpiece. Pull studs also save more than single-ply solid rivets.Read more